A manufacturer of ultra-low carbon building products is proving that you don’t have to abandon traditional building methods to radically improve your sustainability credentials

It is now widely recognised that if we are to achieve our carbon reduction targets the materials we use will need to change. Brick is a staple of the construction industry, but its manufacture is carbon intensive. Moreover, of the 2.5 billion bricks used in the UK annually, over 500 million are imported. With around 50 million of these travelling from outside the EU, there’s clear environmental harm in terms of energy miles. Added to that is the fact that construction, demolition and excavation waste accounts for approximately 60-65% of total waste generated in this country.

Dr Samuel Chapman is Executive Director and co-founder of Kenoteq, a company that’s dedicated to delivering sustainable building materials. His background in structural engineering and architectural design, together with a PhD in life cycle carbon assessment, gives him invaluable insight into what the

sector needs to achieve its green ambitions, and the result is an ultra-low carbon masonry solution.

Waste & recycling

K-BRIQ was developed at Edinburgh’s Heriot-Watt University by Sam and his colleague Professor Gabriela Madero. That was eleven years ago and today a production facility outside of the Scottish capital is proving that the product has a viable commercial future.

“It all started with a chance meeting between Prof Medero and David Hamilton of Hamilton Waste & Recycling,” recalls Sam. “The company were looking at exploring new ways to process construction materials sustainably, and the idea for K-BRIQ emerged as a way of improving the life carbon cycle of waste.”

The latest milestone is British Board of Agrément (BBA) certification. Achieving the standards set by the UK’s leading construction certification body means it can now be specified on a much wider range of construction projects. With no method of testing in place for a non traditional brick, such as K-BRIQ, the product was, in fact, subjected to a rigorous testing regime over many years.

The patented K-BRIQ is produced from nearly 100% recycled construction and demolition waste, with the addition of a binder and is hydraulically compressed rather than kiln fired. All that, together with low temperature curing, adds up to a brick with dramatically reduced CO2 production in its manufacture.

With a standard two-bedroom house in the UK typically requiring around 12,000 bricks, using a standard clay brick creates 5.46 tonnes of CO2e, a more comprehensive measurement than CO2 alone. Building with the K-BRIQ, in contrast, creates 0.2 tonnes of CO2e.

“It takes just 24 hours to transform the raw material to a product that can be laid,” enthuses Sam. “That means we can respond to demand very quickly.” The proprietary binder itself is a closely guarded secret but the waste material in K-BRIQ is readily available. Indeed, one of the advantages of the Kenoteq solution is that it makes use of the likes of gypsum from plasterboard waste, which is itself problematic to dispose of in landfill. Gypsum is a sulphate, and when exposed to organic matter in landfill it produces toxic hydrogen sulphide gas. Other ingredients include recycled aggregates, brick and concrete.

“Unlike approaches that simply treat the symptoms of construction’s environmental impact, the K-BRIQ addresses the root cause by directly tackling the waste crisis while delivering a product that performs exactly like traditional materials, including clay brick.” Sam Chapman, co-founder and executive director of Kenoteq

Builders’ merchants

So what’s the future for K-BRIQ? It’s already been used on some very prestigious projects, is available through selected builders’ merchants, and the ambition is to set up a franchise model so that it can be produced close to local markets, and to recycling centres.

“We’ve estimated that you can make up to 2 ½ billion bricks annually just from the recycled aggregate in the system,” continues Sam, “so there’s no shortage of waste. We can currently produce 2 million bricks a year, and we aim to increase that production capacity to 4 million. That still makes us a relatively small player in the market but the potential for growth is huge.”

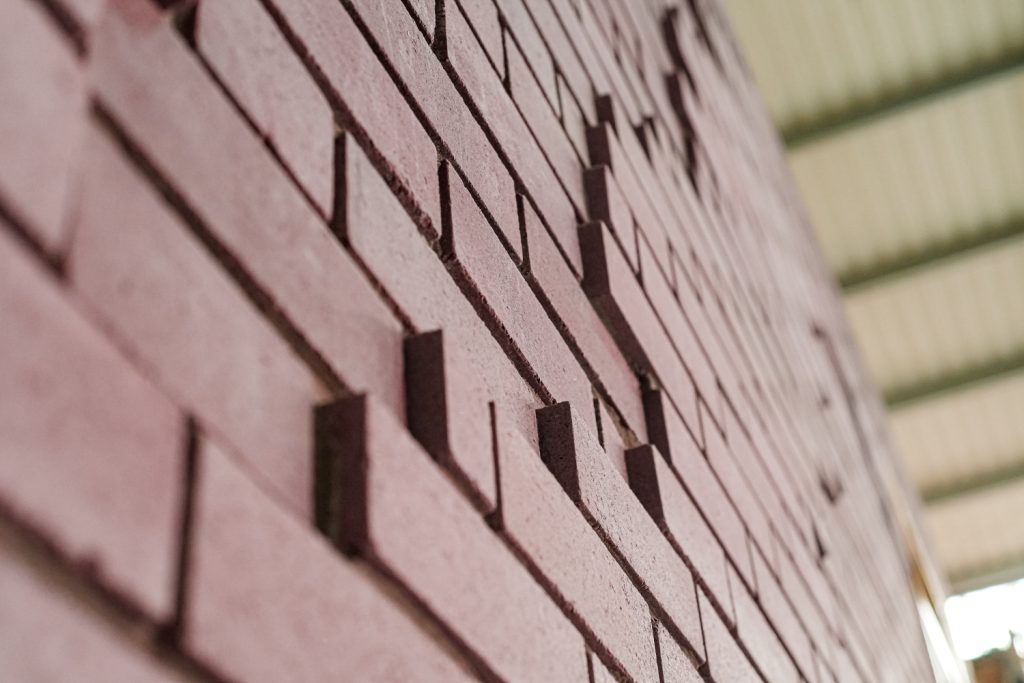

K-BRIQ has an affinity with SME and regional housebuilders and contractors who are building on quality rather than quantity and are looking to differentiate their builds, often for private clients or architects. A 12 strong colour palette provides a whole range of design possibilities, with the pigments again sourced from recycled material.

The durability, freeze thaw and acoustic characteristics are equivalent to a clay fired brick, and the experience for the bricklayer is exactly the same, including the use of a standard cement mortar – although Kenoteq is also recommending the use of lime mortar where feasible. It is equally worth noting that K-BRIQ achieved the maximum durability rating possible from the BBA, whilst the Medero Dark Grey K-BRIQ variant achieved an A-class fire rating, allowing its use in buildings classed as the highest risk.

“We believe that products like K-BRIQ can make a real difference and not just in terms of the circular economy,” concludes Sam. “When you consider that half of the carbon footprint associated with a new building is in the embedded CO2 in the materials then the impact on the industry’s sustainability can clearly be very dramatic.”

For further information on K-BRIQ from Kenoteq click here.